PiControl Solutions LLC engineers were special guests on The Automation Blog podcast (https://theautomationblog.com/picontrol-pid-loop-tuning/), presenting PITOPS: the latest process control technology for full-blown Multivariable Closed-Loop System Identification, PID Tuning and Advanced Process Control (APC) Design and Optimization.

System Identification (or Model Identification) is the procedure or method of finding optimal values for process model parameters. Knowledge of process models gives powerful capability to any process control user of any PLC (such as SIEMENS, ABB, Allen-Bradley, Mitsubishi Electric or Schneider Electric) and/or DCS (such as Honeywell, Emerson, Yokogawa, ABB, Siemens) to:

- mathematically calculate PID tuning parameters of any PID controller

- mathematically calculate PLC/DCS-based Advanced Process Control (APC) parameters (such as Feedforward Lead/Lag and gain, Inferential or Deadtime compensator control, Adaptive control, etc.)

- design accurate and powerful Model Predictive Controller (MPC).

Optimal PID controllers, appropriately designed PLC/DCS-based Advanced Process Controllers (APC) and/or Model Predictive Controllers (MPC) can help any industrial plant to:

- maximize production

- minimize utilities

- minimize waste and off-spec product

- reduce unplanned shut-downs

- provide faster grade transitions

- achieve faster new conditions

- improve stability and increasing safety

- assist operator to avoid mistakes

- improve automation level

There are a few ways how to do proper system identification and certain tools are available for this purpose, but unfortunately most of the them needs step tests on PID OP in Manual mode (Open-Loop step tests), and a few of them can do it by having step tests on PID SP in Auto mode (Closed-Loop step tests). These step tests of a PID OP in Manual mode or PID SP in Auto mode many times are not possible, time-consuming or plant intrusive, and engineers and operators do like them a lot. During steps tests the plant many times will be in upset or spec-off mode, or even working at lower capacity than usual.

PiControl Solutions has created full-blown Multivariable Closed-Loop System Identification technology, called PITOPS. PITOPS can take past data from any PLC or DCS historian during start-up/shutdown or normal plant operation and without any additional time-consuming and intrusive step tests can identify true and accurate process models from:

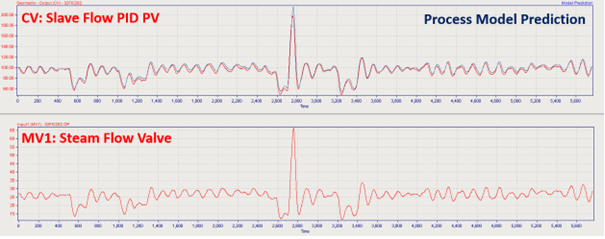

- PID loops being complete in Auto or even in Cascade mode (where the user does not have to break the Cascade chain or set the loop in Manual), as presented on the picture below.

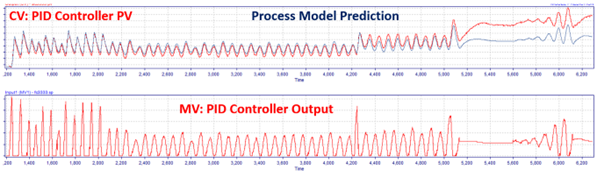

- PID loops being completely oscillatory (unstable) in Auto/Cas mode, as presented on the picture below.

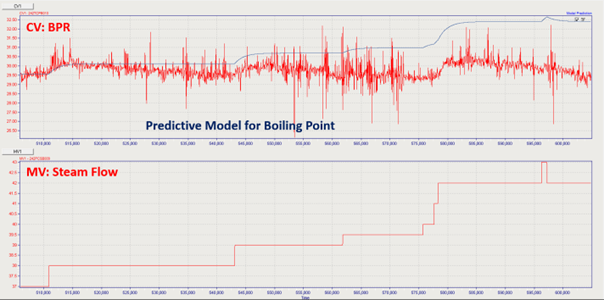

- PID loops impacted with high noise and unmeasured disturbances in Auto/Cas mode, as presented on the picture below.

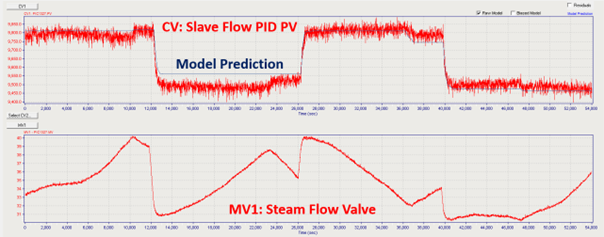

- PID loops having valve issues (stiction/hysteresis) and running in Auto or Cas mode, as presented on the picture below.

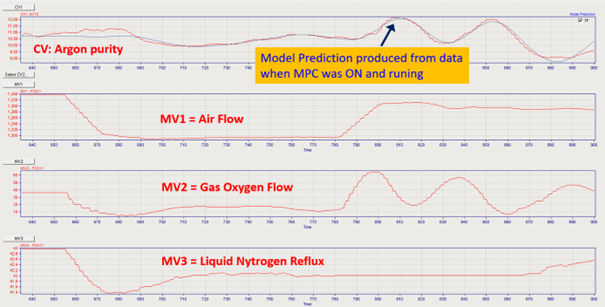

- Running MPC controller (being ON, where the user does not have to put them off)

All mentioned options above reduces intrusive and time-consuming plant step-tests and save the plant of running in undesirable conditions.

Except able to do powerful system identification, PITOPS can also do multi-objective PID loop tuning. 95+ % of PID loop tuning technologies can only tune PID loops based on the step Setpoint change. In any industrial plant there are PID loops which:

- do not change their setpoints regularly (mostly barely)

- PID loops which have continuous and dominant disturbances

- PID loops which have complex setpoint trajectory changes (like all Cascade PID loops)

- PID loops which have valve issues

- PID loops which valves cannot be changed abruptly since it may cause some serious downstream upsets, and so on.

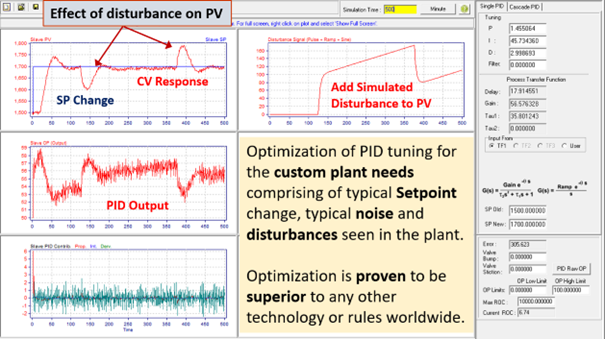

Since each PID loop has its own purpose and objective, it is unreasonable to tune all PID loops only based on the step setpoint change. This simplified PID tuning on a typical step setpoint change will produce poor and not optimal PID loop behavior, which will not be able to produce optimal control action needful to reject process disturbances or to handle control valve mechanical issues. Therefore, PiControl Solutions has invented technology which can accurately tune PID control loops based on the following multi-objective approach:

- Step/ramp or even complex SP changes (Cascade loops)

- Disturbances (Pulse, Step, Ramp, Sine)

- Noise

- PID OP rate of change

- Control valve stiction

- Non-linear process gains and/or process dynamics

Now, process control user/expert can finally get optimal PID tuning parameters based on real PID loops needs and objectives, and stop the era of trial-and-error or guessing tuning of PID loops, as presented on the picture below.